No Bubbles, No Hassle: The Ultimate Skin Application Guide

No Bubbles, No Hassle: The Ultimate Skin Application Guide

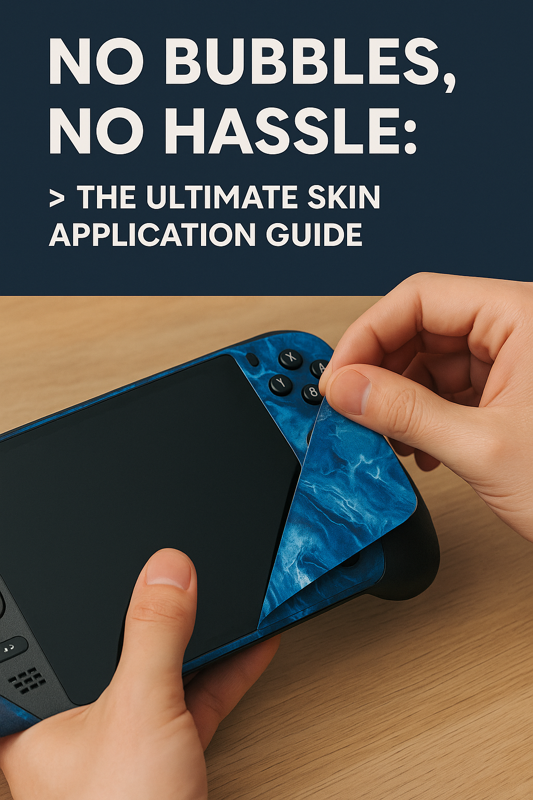

Transform your camera and gadgets with professional-looking results using our proven 6-step method that eliminates bubbles and ensures perfect placement every time.

Applying a device skin shouldn't feel like rocket science, yet so many people struggle with bubbles, misalignment, and frustrating results. The secret isn't having magical hands—it's following a systematic approach that professional installers have refined over years of experience. At CAMSKNS, we've distilled this expertise into a simple 6-step process that guarantees success, whether you're customizing your first smartphone or your tenth camera body.

Our method works because it's built around the unique properties of CAMSKNS Edge™ vinyl and addresses the most common installation mistakes before they happen. By the end of this guide, you'll have the confidence and knowledge to achieve flawless results that rival professional installations.

Why Perfect Application Matters for Your Gear

Your camera, gaming console, or smartphone represents a significant investment—often thousands of dollars of precision engineering. A properly applied skin doesn't just customize appearance; it provides crucial protection against scratches, fingerprints, and daily wear while maintaining your device's resale value.

The difference between amateur and professional results comes down to preparation and technique. Rushed installations lead to bubbles, poor adhesion, and premature failure. Our systematic approach eliminates these issues by controlling every variable that affects installation quality.

Modern device skins have evolved far beyond simple stickers. CAMSKNS Edge™ vinyl represents the cutting edge of wrap technology, offering superior conformability and adhesion that makes professional results achievable for everyone. Understanding how to work with this advanced material is the key to installation success.

Understanding CAMSKNS Edge™ Technology

Before diving into our application method, it's essential to understand what makes CAMSKNS Edge™ vinyl superior to standard materials.

Revolutionary Material Properties:

Precision Thickness: CAMSKNS Edge™ is significantly thinner than generic vinyl, allowing for sharper lines and more precise corner wrapping. This reduction in thickness translates directly to easier installation and more professional appearance.

Enhanced Conformability: The advanced polymer structure makes our vinyl more flexible around complex curves and tight radius bends. This means fewer bubbles and smoother application on challenging surfaces like camera grips and curved edges.

Professional-Grade Adhesive: Our pressure-activated adhesive system creates strong bonds with clean surfaces while allowing for repositioning during installation. This forgiveness is crucial for achieving perfect alignment.

Weather Resistance: Rated for 6+ years of outdoor durability, CAMSKNS Edge™ withstands UV exposure, temperature fluctuations, and moisture without degrading or losing adhesion.

Real-World Performance: Originally developed for commercial applications, this vinyl brings wrap shop quality to consumer installations, ensuring your customization looks professional and lasts.

Essential Tools and Preparation

Success begins before you even touch the skin. Having the right tools and workspace dramatically improves your results and reduces installation stress.

Required Tools:

- Clean, lint-free cloth or microfiber towel

- Hair dryer with low heat setting

- Precision tweezers (optional but recommended)

- Good lighting source

- Clean, dust-free workspace

Workspace Setup: Choose a well-lit area away from high-traffic zones where dust and lint circulate. Natural lighting is ideal for spotting imperfections and ensuring proper alignment. Clear your workspace completely—you'll need room to maneuver and lay out skin pieces.

Time Allocation: Plan for 20-30 minutes of focused installation time. Rushing leads to mistakes, while taking your time ensures professional results. This isn't a quick five-minute job—treat it as a precision craft project.

The CAMSKNS 6-Step Method: Detailed Breakdown

Step 1: Clean Your Camera or Gadget

This step determines 70% of your installation success. Even microscopic contaminants can cause bubbles, poor adhesion, and premature failure.

Surface Preparation Process:

Power down your device completely and remove any cases, straps, or accessories. You need complete access to all surfaces where the skin will adhere.

Start with a thorough wipe-down using a clean, lint-free cloth. Focus on removing visible dust, fingerprint oils, and any debris. Pay special attention to textured areas like camera grips, button recesses, and port openings where contaminants typically accumulate.

Deep Cleaning Technique: For optimal results, use isopropyl alcohol (91% or higher) on your cloth. This removes invisible oils and residues that standard dry cleaning misses. Allow surfaces to dry completely before proceeding—any remaining moisture will interfere with adhesion.

Critical Areas: Don't overlook corners, edges, and transitions between materials. These areas are bubble-prone if contaminated. Use compressed air if available to remove particles from button recesses and tight spaces.

Quality Check: Your surface should feel completely clean and smooth to the touch. Any roughness, stickiness, or visible particles require additional cleaning.

Step 2: Peel Away the Excess Vinyl

Precision cutting preparation sets up perfect alignment. This step transforms your skin kit from a sheet of vinyl into precisely positioned installation pieces.

Excess Removal Process:

Examine your skin sheet carefully, identifying the actual skin pieces versus the excess vinyl surrounding them. CAMSKNS skins are precision laser-cut, leaving minimal excess material, but removing this excess is crucial for clean handling.

Technique: Using your fingernail or tweezers, carefully lift and peel away the surrounding vinyl. Work slowly to avoid accidentally removing actual skin pieces. The precision cutting means there's a clear distinction between skin pieces and waste material.

Organization Strategy: As you remove excess vinyl, organize the skin pieces on a clean surface in the order you'll apply them. This prevents confusion during installation and ensures you don't lose small pieces.

Backing Paper Management: Leave the backing paper on all pieces until you're ready to apply each one. Premature backing removal leads to contamination and handling difficulties.

Step 3: Plan Your Placement

Alignment planning prevents 90% of installation disasters. This step is about visualization and strategy, not actual application.

Strategic Positioning:

Hold each skin piece over its intended location without removing any backing paper. Study how cutouts align with buttons, ports, and camera openings. Perfect alignment here is non-negotiable—even small misalignments become obvious once applied.

Critical Alignment Points:

- Camera lens openings (zero tolerance for error)

- Button cutouts (should have even spacing)

- Port access (must maintain full functionality)

- Brand logos or text (parallel to device edges)

- Seam locations on multi-piece designs

Mental Rehearsal: Practice the motion of applying each piece. Visualize where you'll start application and how you'll smooth out air bubbles. This mental preparation significantly improves actual application accuracy.

Complexity Assessment: Identify the most challenging pieces—usually those with complex curves or multiple cutouts. Plan to tackle these when you're fresh and focused, typically starting with simpler pieces to build confidence.

Step 4: Apply the Skin

This is where preparation pays off. With proper planning and clean surfaces, application becomes a controlled, methodical process rather than a stressful gamble.

Application Sequence:

Start with the largest, simplest pieces to build confidence and establish reference points for remaining pieces. Remove backing paper from your first piece, taking care not to touch the adhesive side.

Alignment Technique: Position the piece according to your planning, but don't press down yet. Make final alignment adjustments while you can still lift and reposition. CAMSKNS Edge™ adhesive allows for repositioning during initial placement, but this window is limited.

The Progressive Press Method: Once perfectly aligned, start pressing from one edge and work systematically across the surface. Use firm, consistent pressure to activate the adhesive and eliminate air pockets. The key is controlling air displacement—trapped air creates bubbles.

Pressure Control: Apply enough pressure to activate the adhesive without stretching the vinyl. CAMSKNS Edge™ material is forgiving, but excessive force can create permanent distortion or adhesive squeeze-out.

Tweezers Usage: For small pieces or intricate cutouts, tweezers provide the precision control that fingers can't match. They're especially valuable for positioning pieces around complex camera controls or port openings.

Multi-Piece Coordination: When applying multiple pieces, work systematically to ensure proper seam alignment and consistent appearance. Each piece should complement the others for a unified look.

Step 5: Use Gentle Heat

Heat activation transforms good adhesion into permanent bonding. This step is where CAMSKNS Edge™'s advanced formulation really shines.

Heat Application Strategy:

Set your hair dryer to low heat—excessive temperature can damage the vinyl or create handling difficulties. Hold the dryer 6-8 inches away from the surface and apply heat in short, sweeping motions rather than concentrating on one area.

Temperature Monitoring: The vinyl should feel warm but not hot to the touch. Proper temperature makes the material more pliable and activates the adhesive for stronger bonding.

Curve Conforming: Heat is especially critical around curved surfaces like camera grips, lens barrels, and device edges. The warmth allows CAMSKNS Edge™ vinyl to stretch slightly and conform to complex geometries without creating wrinkles or bubbles.

Edge Sealing: Focus extra attention on edges and corners where lifting typically occurs. Apply heat while pressing firmly to create a permanent seal that resists moisture and debris infiltration.

Cooling Period: After heat application, allow the vinyl to cool while maintaining pressure. This cooling under pressure creates optimal adhesive bonding and prevents future lifting.

Complex Geometry Technique: For deep recesses like button areas, apply heat, press the vinyl into the recess, then apply additional heat while maintaining pressure. This ensures complete conforming without air pockets.

Step 6: Show It Off

Quality control and celebration complete the process. This final step ensures your installation meets professional standards and connects you with the CAMSKNS community.

Final Inspection Protocol:

Examine your installation under good lighting, checking for:

- Complete edge adhesion along all perimeters

- Proper cutout alignment and functionality

- Smooth surface finish without bubbles or wrinkles

- Clean seam lines on multi-piece installations

Functional Testing: Verify that all buttons, ports, and moving parts operate smoothly. A properly applied skin should never interfere with device functionality.

24-Hour Rule: While CAMSKNS Edge™ provides immediate strong adhesion, full bond strength develops over 24 hours. Avoid heavy use during this period to ensure optimal long-term performance.

Photography Tips: Capture your finished installation from multiple angles, showcasing both the overall transformation and detail work around complex areas. Good lighting reveals the precision of your work and the quality of CAMSKNS materials.

Community Connection: Tag @CAMSKNS on Instagram to share your success and potentially be featured on our social media. The CAMSKNS community loves seeing creative installations and professional-quality results.

Troubleshooting Common Challenges

Small Air Bubbles: Often resolve naturally within 24-48 hours as adhesive settles. For persistent small bubbles, use a pin to create a tiny hole at the edge and smooth air out gently.

Edge Lifting: Usually indicates insufficient cleaning or heat application. Lift the affected area, re-clean if necessary, and reapply with proper heat and pressure.

Alignment Issues: If discovered immediately, CAMSKNS Edge™ allows for careful repositioning. Work quickly—adhesive strength increases rapidly after initial contact.

Complex Curve Problems: Additional heat and patience usually resolve conforming issues. Work in small sections, allowing material to relax between heating cycles.

Professional Tips for Specific Device Types

Camera Bodies: Focus on grip areas where precise fit affects handling comfort. Ensure skins don't interfere with battery compartments, memory card slots, or tripod mounts.

Gaming Controllers: Pay special attention to button feel and stick movement. Properly applied skins shouldn't affect gaming performance.

Smartphones and Tablets: Screen edge precision is critical. Even small overlaps can interfere with screen protectors or case compatibility.

Laptops: Work systematically across large surfaces to prevent bubbles. Use the heat technique extensively for smooth, professional appearance.

Advanced Techniques for Perfect Results

Temperature Management: Ambient temperature affects installation quality. Ideal conditions are 65-75°F with low humidity. Cold conditions require more heat application, while hot conditions may make adhesive too aggressive.

Dust Control: Use anti-static spray in dusty environments. Even microscopic particles can cause visible imperfections under smooth vinyl surfaces.

Seam Planning: For multi-piece installations, plan seam locations to minimize visibility and maximize durability. Avoid placing seams in high-wear areas when possible.

The Science Behind Superior Adhesion

Understanding why proper technique matters helps explain our methodical approach. Modern vinyl adhesives are pressure-activated systems that create molecular bonds with clean surfaces. Contamination, trapped air, or inadequate pressure prevents these bonds from forming, leading to failure points.

CAMSKNS Edge™ features an advanced acrylic adhesive specifically engineered for electronic devices. This adhesive provides strong initial tack while allowing repositioning—crucial for complex installations requiring precise alignment.

Quality Control and Long-Term Performance

Initial Quality Markers:

- No visible bubbles or wrinkles

- Complete edge adhesion

- Perfect cutout alignment

- Smooth, uniform surface finish

Long-Term Maintenance: Properly installed CAMSKNS skins require minimal maintenance. Clean with mild soap and water, avoiding harsh chemicals that might affect the vinyl or adhesive.

Performance Expectations: When properly applied, CAMSKNS Edge™ vinyl provides years of protection and customization. The combination of superior materials and correct installation technique ensures lasting satisfaction.

Why Choose CAMSKNS for Your Customization Needs

At CAMSKNS, we understand that successful device customization requires more than just quality materials—it demands precision manufacturing, innovative adhesive technology, and comprehensive customer support.

Our Commitment to Excellence:

- Precision laser cutting for perfect device fit

- CAMSKNS Edge™ vinyl technology on every product

- Extensive device compatibility across major brands

- Professional-grade materials at accessible prices

- Detailed installation guidance and customer support

Innovation Leadership: We continuously invest in material science and manufacturing technology to provide the best possible customization experience. CAMSKNS Edge™ represents years of development focused on making professional results achievable for everyone.

Ready to transform your gear with confidence? Discover our complete collection of precision-cut device skins at CAMSKNS.com and experience the difference that professional-grade materials and expert guidance make.

Building Your Customization Skills

Mastering device skin installation opens doors to complete gear customization. Many customers start with a single device and expand to wrapping their entire tech ecosystem—cameras, phones, gaming equipment, and laptops.

Skill Development Path:

- Start with simpler geometric devices

- Progress to complex curved surfaces

- Master multi-piece installations

- Develop personal style preferences

Community Learning: Connect with other CAMSKNS customers through social media to share techniques, troubleshoot challenges, and showcase creative installations. The collective knowledge of our community helps everyone achieve better results.

Cost-Effectiveness of DIY Installation

Professional vinyl installation services often charge $100-300 per device, making DIY application incredibly cost-effective. With CAMSKNS skins starting at a fraction of professional installation costs, you can customize multiple devices for less than a single professional job.

Value Proposition: Beyond cost savings, DIY installation provides personal satisfaction and the ability to customize exactly when and how you want. There's genuine pride in achieving professional-quality results through your own skill and attention to detail.

Conclusion: Master the Art of Perfect Installation

Perfect device skin installation combines quality materials, proven technique, and attention to detail. Our 6-step method, developed specifically for CAMSKNS Edge™ vinyl, eliminates guesswork and ensures consistent professional results.

The transformation isn't just visual—properly applied skins protect your investment while expressing personal style. Whether customizing a $3,000 camera system or personalizing a gaming controller, these techniques deliver lasting satisfaction and professional appearance.

Start your customization journey today. Visit CAMSKNS.com to explore our full range of precision-cut device skins, all featuring revolutionary CAMSKNS Edge™ vinyl technology. Your gear deserves the best—and now you have the expertise to deliver it.

From careful surface preparation to final quality control, every step in our process is designed to eliminate common installation problems while maximizing the performance of premium materials. The result is customization that looks professional, feels premium, and lasts for years.

SEO Keywords Targeted:

- device skin application

- camera skin installation

- vinyl skin installation guide

- bubble-free skin application

- CAMSKNS Edge vinyl

- precision device skins

- professional skin installation

- device customization guide

- skin application techniques

- camera skin application method